|

Product Name |

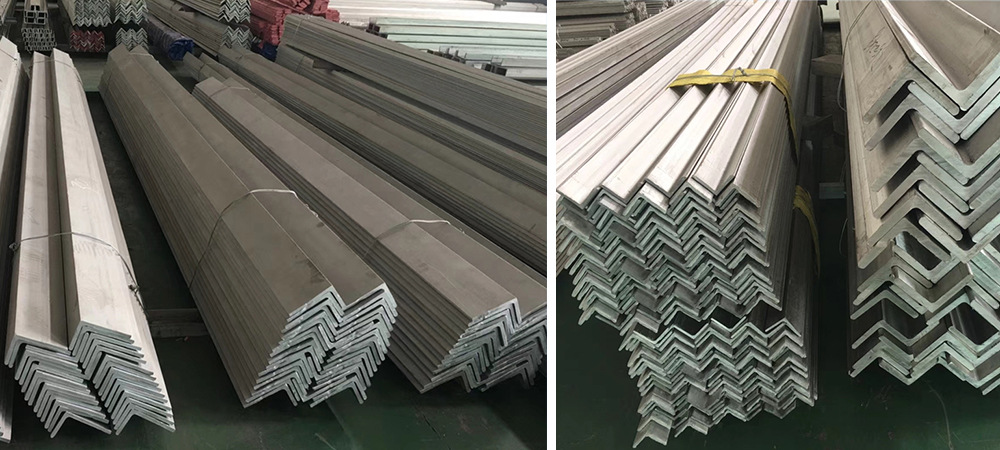

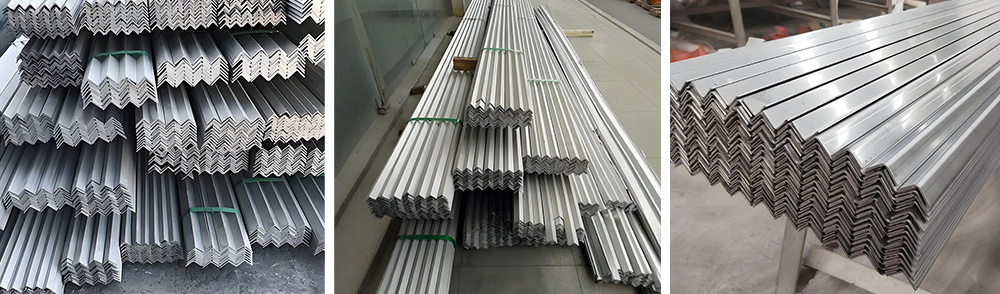

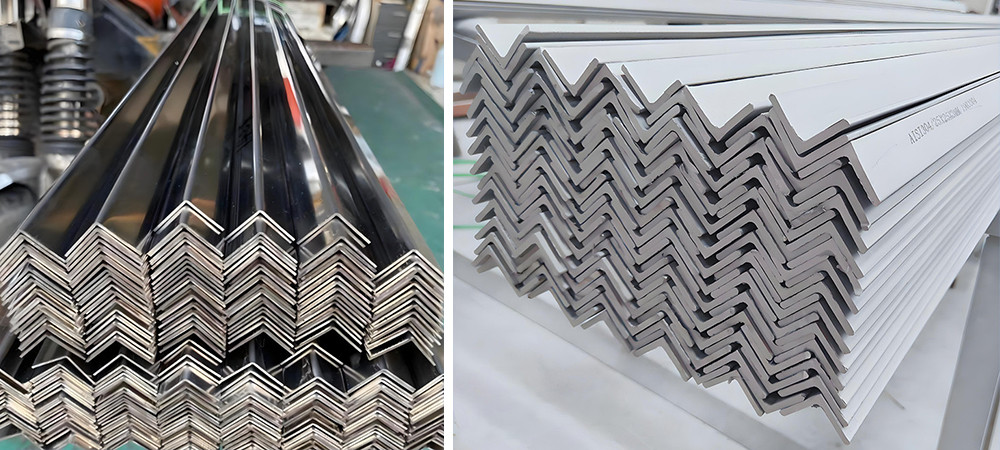

Stainless Steel Angle Bar |

|

Material |

201 202 301 304 304L 316 316L 309S 310S 321 410 420 430 2205 904L etc. |

|

Standard |

ASTM,AISI,SUS,JIS,EN,DIN,BS,GB |

|

Technique |

Cold drawn/hot drawn |

|

Surface |

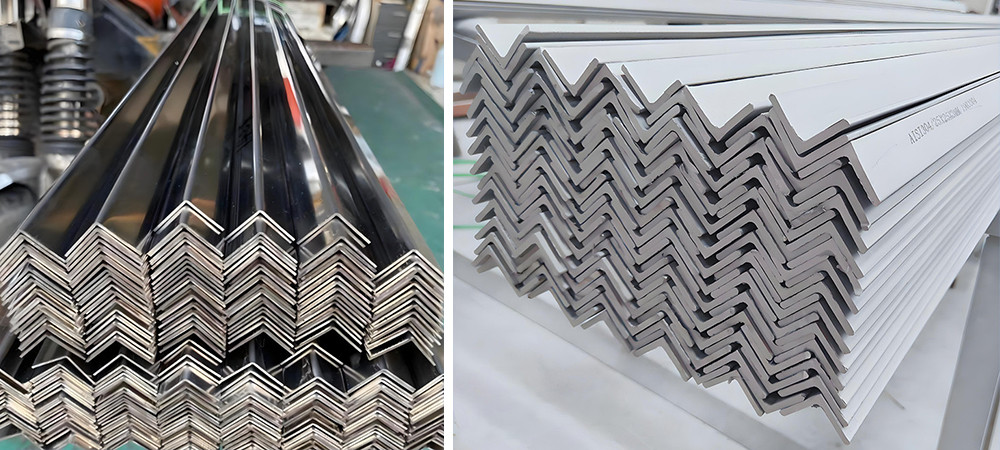

Pickled,bright,polished |

|

Thickness |

3-30mm |

|

Size |

25*25-200*200mm or 40*25-150*75mm |

|

Length |

6m,12m or custom |

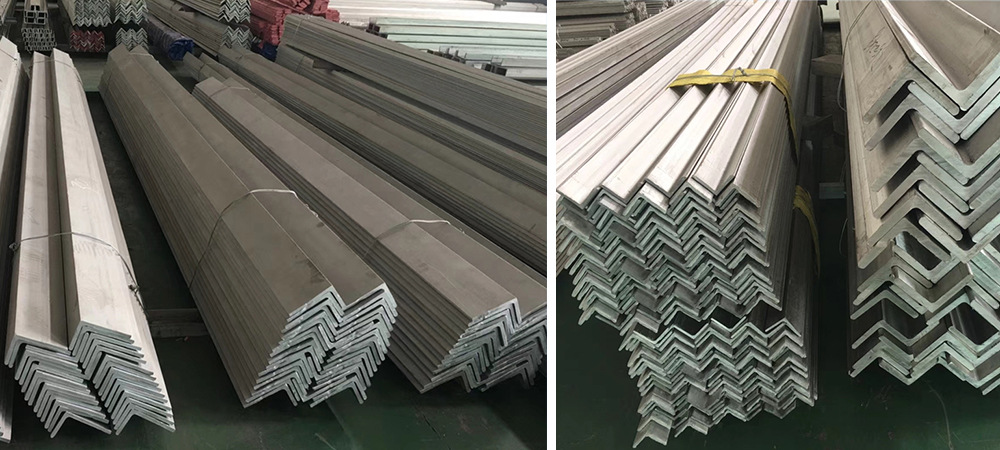

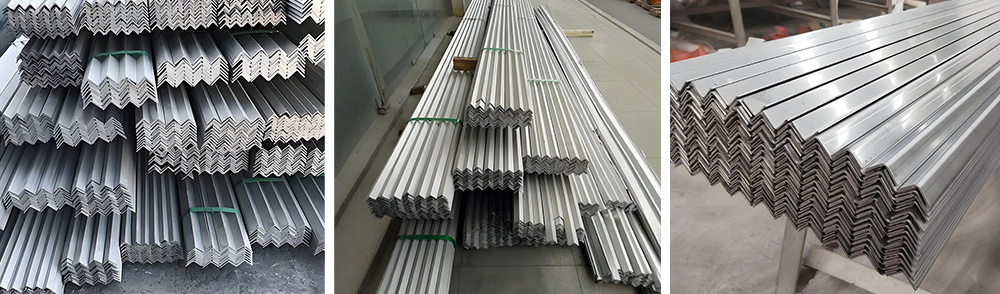

Stainless steel angle bars are essential structural elements widely applied in global construction, marine engineering, machinery production, architectural decoration, and chemical equipment fields. Our products are manufactured with high-quality 201, 304, and 316 stainless steel, which are recognized for outstanding corrosion resistance, high mechanical strength, and long-lasting durability.

The 304 stainless steel angle bars offer excellent rust resistance for general indoor and outdoor use, while 316 grade is specially engineered for harsh environments like coastal areas, chemical plants, and marine projects, resisting chloride corrosion effectively. All angle bars undergo precision rolling technology, ensuring accurate dimensions (25x25mm to 200x200mm), smooth burr-free surfaces, and easy processing such as welding, cutting, and drilling.

We provide both equal and unequal stainless steel angle bars, with customized thicknesses and lengths to fit diverse project demands. Every batch complies with international standards including ASTM A480, DIN EN 10088, and JIS G4305, ensuring consistent quality and compatibility in global projects. These angle bars are ideal for framing, bracing, load-bearing supports, railings, and equipment frames, delivering low maintenance costs and extended service life for your projects. We offer bulk supply, timely delivery, and professional technical support to global buyers.

1.Construction Industry:

1.Construction Industry: Widely used for building frames, wall bracings, floor supports, and railing structures. The corrosion-resistant stainless steel angle bars ensure long-term stability in indoor and outdoor construction projects, complying with global building standards.

2.Marine Engineering: Applied in ship hull framing, offshore platform supports, and coastal facility construction. 316 stainless steel angle bars resist chloride corrosion from seawater, making them ideal for harsh marine environments.

3.Machinery Manufacturing: Used to fabricate equipment frames, machine bases, and structural brackets. Precise dimensions and high mechanical strength of the angle bars guarantee stable performance of mechanical equipment.

4.Chemical & Pharmaceutical Equipment: Suitable for manufacturing chemical tanks, pipeline supports, and pharmaceutical production lines. The rust-resistant feature prevents contamination and ensures compliance with industry hygiene standards.

5.Architectural Decoration: Utilized in decorative railings, door/window frames, and interior/exterior decorative structures. Smooth surface finish of stainless steel angle bars enhances aesthetic appeal while maintaining durability.

6.Automotive & Aerospace: Applied in auto chassis brackets, aircraft component frames, and auxiliary structural parts. Lightweight and corrosion-resistant properties meet strict industry performance requirements.